In the world of automotive repairs and upgrades, it’s essential to know how to choose the right size exhaust clamp for your car. These seemingly small metal bands play a crucial role in keeping your exhaust system secure and leak-free. But with various sizes and options available, how do you ensure you’re making the right choice? This article aims to guide you through the process, providing valuable tips and insights that will help you select the perfect exhaust clamp for your car without any hassle. So, let’s dive in and discover the secrets to finding the ideal fit for your vehicle’s exhaust system.

Understanding the Purpose of the Exhaust Clamp in Your Vehicle

When it comes to the efficiency and proper functioning of your vehicle’s exhaust system, there is one vital component that often goes unnoticed but plays a crucial role – the exhaust clamp. The exhaust clamp is a simple yet essential device that serves to securely hold the various components of your exhaust system together. Without a properly functioning exhaust clamp, your vehicle’s exhaust system would be prone to leaks, which can lead to diminished performance, increased emissions, and even potential safety hazards. Understanding the purpose of the exhaust clamp is necessary to ensure the smooth operation of your vehicle.

What is an Exhaust Clamp?

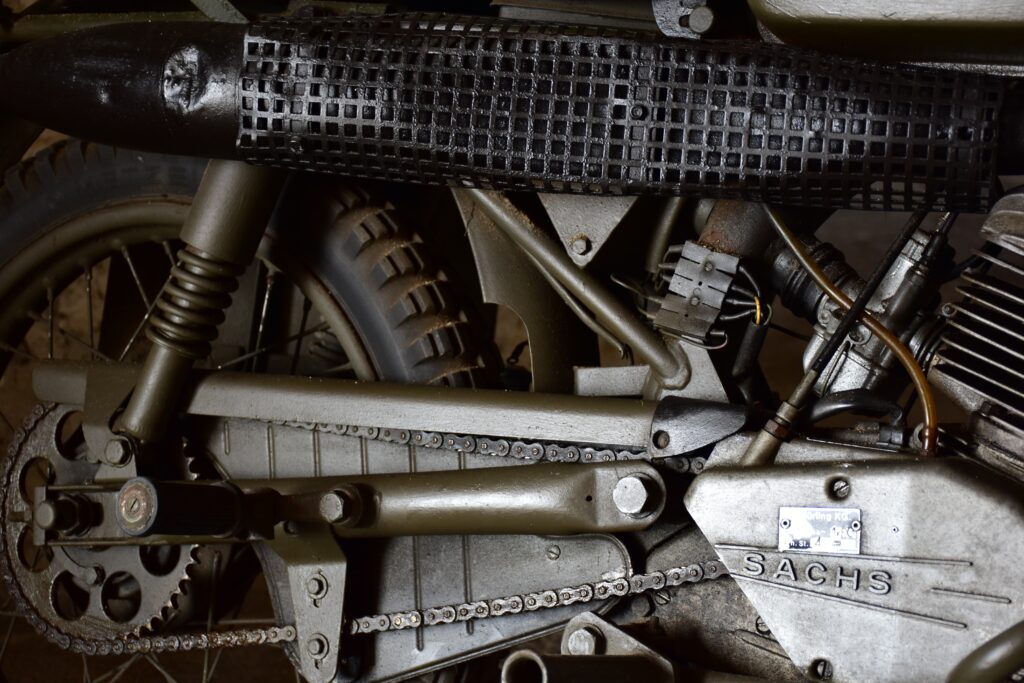

An exhaust clamp is a mechanical device designed to join and secure the exhaust pipe and other components of the exhaust system in your vehicle. It is generally made of a durable and heat-resistant material such as stainless steel, aluminum, or cast iron. The primary objective of the exhaust clamp is to create a tight seal between the joints in the exhaust system, preventing any exhaust gases from leaking out. By maintaining a proper seal, the exhaust clamp not only ensures the efficient expulsion of exhaust gases but also minimizes noise and vibrations.

Function of the Exhaust Clamp

The function of the exhaust clamp goes beyond merely holding the exhaust components together. It plays a critical role in maintaining the overall integrity of the exhaust system. Without a secure clamp, the joints between the components of the exhaust system would be susceptible to leaks. These leaks can interfere with the proper flow of exhaust gases, leading to reduced engine performance and increased emissions. Furthermore, exhaust leaks can also allow harmful gases, such as carbon monoxide, to enter the cabin of the vehicle, posing a serious health hazard to the occupants. In summary, the primary function of the exhaust clamp is to create a secure and airtight connection between the various components of the exhaust system, ensuring optimal performance and safety.

Knowing Your Car

Before selecting the right exhaust clamp for your vehicle, it is essential to have a good understanding of your car. This includes knowing your vehicle’s make and model and familiarizing yourself with its exhaust system.

Getting to Know Your Vehicle’s Make and Model

To choose the right size exhaust clamp for your car, you need to be aware of the specific make and model of your vehicle. This information can usually be found in your vehicle’s documentation, such as the owner’s manual or registration papers. Alternatively, you can also find this information by inspecting your car’s VIN (Vehicle Identification Number), which is typically located on the driver’s side dashboard or door jamb. Having the correct make and model information will help ensure that you select an exhaust clamp that is compatible with your specific vehicle.

Understanding Your Vehicle’s Exhaust System

To accurately determine the size and type of exhaust clamp needed for your vehicle, it is crucial to understand your car’s exhaust system. The exhaust system is responsible for collecting and expelling the harmful gases produced during the combustion process. It typically consists of several components, including the exhaust manifold, catalytic converter, muffler, and tailpipe. Each of these components plays a vital role in reducing emissions, dampening noise, and directing exhaust gases away from the vehicle. By familiarizing yourself with your vehicle’s exhaust system, you can better understand how the exhaust clamp fits into the overall system and select the appropriate clamp for your needs.

Measuring Your Car’s Exhaust Pipe Diameter

Accurately measuring your car’s exhaust pipe diameter is essential when choosing the right size exhaust clamp. Here’s a step-by-step guide on how to measure your exhaust pipe effectively:

How to Accurately Measure Your Exhaust Pipe

- Start by locating the exhaust pipe underneath your vehicle. It is usually located at the rear, extending from the muffler or catalytic converter.

- Use a tape measure or caliper to measure the outside diameter of the exhaust pipe. The outside diameter is the distance from one outer edge of the pipe to the opposite outer edge, passing through the center. Ensure that the measurement is taken at a straight portion of the pipe, without any bends or curves.

- Take note of the measured diameter in either inches or millimeters, depending on the unit of measurement used by the exhaust clamp manufacturer.

Tools Needed for Measuring Exhaust Pipe

To accurately measure your car’s exhaust pipe, you will need a few tools:

- Tape measure or caliper: This tool will allow you to determine the outside diameter of the exhaust pipe accurately. Make sure it is long enough to span the diameter of the pipe.

- Safety gloves: When working underneath your vehicle, it is always recommended to wear safety gloves to protect your hands.

By following these simple steps and using the necessary tools, you can ensure an accurate measurement of your car’s exhaust pipe diameter. This measurement will serve as a crucial factor in selecting the right size exhaust clamp for your vehicle.

Knowing the Different Types of Exhaust Clamps

Exhaust clamps come in various types, each with its own advantages and suitable applications. Here are the most common types of exhaust clamps:

U-bolt Exhaust Clamps

U-bolt exhaust clamps are a popular option due to their simple and reliable design. As the name suggests, these clamps feature a U-shaped bolt that is tightened around the exhaust pipe using nuts. The U-bolt design provides a secure and strong connection, making these clamps suitable for heavy-duty applications. U-bolt clamps are commonly used in commercial vehicles, heavy machinery, and large exhaust systems.

Band Clamps

Band clamps, also known as strap clamps, consist of a metal band that wraps around the exhaust pipe and is fastened using bolts or screws. These clamps offer excellent versatility as they can be easily adjusted and reused. Band clamps are suitable for various exhaust system joints and are often used in aftermarket exhaust installations.

V-band Clamps

V-band clamps are designed to provide a quick and secure connection between two pipes by utilizing a V-shaped clamp and an accompanying flange. These clamps offer high clamping force, ensuring a tight seal and minimizing the risk of exhaust leaks. V-band clamps are commonly used in high-performance and turbocharged applications.

Lap Joint Clamps

Lap joint clamps, also known as butt joint clamps, are intended for connecting pipes with overlapping ends. These clamps feature a lap joint design, with both ends of the clamp overlapping each other. Lap joint clamps are easy to install and provide an effective seal, making them suitable for most exhaust system connections.

By understanding the different types of exhaust clamps, you can select the one that best suits your specific needs and ensures a secure and leak-free connection in your vehicle’s exhaust system.

Choosing the Exhaust Clamp Material

When selecting an exhaust clamp, it is crucial to consider the material it is made from. Different materials offer varying levels of durability, corrosion resistance, and heat tolerance. Here are the most common materials used for exhaust clamps:

Stainless Steel Clamps

Stainless steel clamps are highly popular due to their excellent corrosion resistance, durability, and heat tolerance. They are resistant to rust and other forms of corrosion, making them suitable for a wide range of environments and climates. Stainless steel clamps are commonly used in both automotive and industrial applications.

Aluminum Clamps

Aluminum clamps offer a lightweight and cost-effective solution for securing exhaust system components. They are particularly advantageous in terms of weight reduction and ease of installation. However, aluminum clamps may not be as durable as stainless steel clamps and may be more susceptible to corrosion and heat damage in certain environments.

Cast Iron Clamps

Cast iron clamps offer exceptional heat resistance and durability, making them suitable for high-temperature exhaust systems. They are commonly used in heavy-duty applications or in vehicles that operate under extreme conditions. However, cast iron clamps may be heavier and more expensive compared to other materials.

By considering the specific characteristics and requirements of your vehicle’s exhaust system, you can choose the appropriate clamp material that ensures long-lasting performance and reliability.

Identification of Current Clamp Size

Before replacing your exhaust clamp, it is crucial to identify the size of the existing clamp. This will help ensure that you select a replacement clamp that matches the dimensions and specifications of your current clamp. Here’s how you can identify the size of your current clamp:

Inspecting the Current Clamp

Begin by visually inspecting the existing exhaust clamp. Pay attention to any markings or engravings on the clamp itself, as they may indicate its size, model, or brand. However, not all clamps will have visible markings, so additional measurements may be necessary.

Measuring the Current Clamp

Using a tape measure or caliper, measure the size of the existing clamp. Take note of the width, length, and diameter of the clamp to ensure a precise match when selecting a replacement. It is recommended to measure the clamp at multiple points to account for any irregularities.

By accurately identifying the size of your current clamp, you can confidently choose a replacement that fits seamlessly into your vehicle’s exhaust system.

When to Replace Your Exhaust Clamp

Just like any other automotive component, exhaust clamps can wear out over time due to factors such as heat exposure, corrosion, and vibrations. It is crucial to recognize the signs of a worn-out exhaust clamp to prevent potential issues. Here are a few indications that it may be time to replace your exhaust clamp:

Signs of a Worn-Out Exhaust Clamp

- Visible signs of rust or corrosion on the clamp

- Loose or rattling sound coming from the exhaust system

- Noticeable exhaust leaks, such as hissing or popping sounds

- Increased fuel consumption

- Reduced engine performance or acceleration

- Exhaust smell inside the vehicle’s cabin

If you notice any of these signs, it is advisable to have your exhaust system inspected by a qualified professional. Replacing a worn-out exhaust clamp in a timely manner can help prevent further damage to your vehicle and ensure the proper functioning of the exhaust system.

Potential Risks with Not Replacing a Faulty Clamp

Neglecting to replace a faulty exhaust clamp can lead to various risks and consequences. These include:

- Increased emissions: A faulty clamp can cause exhaust leaks, leading to increased emissions of harmful gases into the environment.

- Reduced fuel efficiency: Leaks in the exhaust system can disrupt the proper flow of exhaust gases, resulting in decreased fuel efficiency and increased fuel consumption.

- Engine damage: If exhaust leaks are not addressed, they can eventually lead to damage to the internal components of the engine, potentially resulting in costly repairs.

To avoid these potential risks, it is essential to regularly inspect your exhaust system and promptly replace any worn-out or faulty clamps.

Maintaining Your Exhaust Clamp

To ensure the longevity and optimal performance of your exhaust clamp, regular maintenance is crucial. Here are a few tips to keep your exhaust clamp in good condition:

How to Keep Your Exhaust Clamp in Good Condition

- Regular visual inspection: Periodically inspect your exhaust clamp for signs of rust, corrosion, or damage. If any issues are detected, take appropriate action, such as cleaning, lubricating, or replacing the clamp.

- Avoid excessive heat exposure: Exhaust clamps are exposed to high temperatures, which can accelerate corrosion and deterioration. Limiting prolonged exposure to extreme heat, such as parking near hot surfaces, can help extend the lifespan of the clamp.

- Cleanliness: Maintaining a clean exhaust system can prevent the buildup of dirt, debris, and corrosive materials, which can potentially affect the clamp’s performance. Regularly clean the exhaust system, paying close attention to the area around the clamp.

- Professional inspection: For optimal maintenance, consider having your exhaust system and clamp inspected by a qualified automotive professional. They can identify any potential issues and provide necessary repairs or replacements.

By following these maintenance practices, you can ensure the longevity and reliability of your exhaust clamp, contributing to the overall performance and efficiency of your vehicle’s exhaust system.

Regular Checks for Exhaust Clamp

Regular checks for your exhaust clamp should be an integral part of your vehicle maintenance routine. By inspecting the exhaust clamp at regular intervals, you can identify any signs of wear and detect potential issues before they escalate into significant problems. Here are a few recommendations for conducting regular checks on your exhaust clamp:

- Visual inspection: Visually examine the exhaust clamp for any visible signs of rust, corrosion, or damage. Pay close attention to the connections and welds, looking for any cracks or gaps.

- Listen for abnormal noises: During vehicle operation, listen for any unusual rattling, hissing, or popping sounds that may indicate a loose or faulty exhaust clamp. These noises could be a sign of leaks in the exhaust system.

- Check for exhaust leaks: Inspect the area around the clamp for any signs of exhaust leaks, such as black soot or residue. You can also perform a simple test by blocking the tailpipe momentarily, observing if any exhaust gas escapes from the clamp or any other joints.

- Monitor performance: Keep an eye on any changes in your vehicle’s performance, such as reduced acceleration, increased fuel consumption, or unusual engine noise. These could be indicators of a faulty exhaust clamp or other exhaust system issues.

By incorporating regular checks for your exhaust clamp into your vehicle maintenance routine, you can ensure the continued functionality and safety of your exhaust system.

In conclusion, understanding the purpose of the exhaust clamp, knowing your car, measuring your car’s exhaust pipe diameter accurately, knowing the different types of exhaust clamps, choosing the right material, identifying the current clamp size, knowing when to replace your exhaust clamp, and maintaining your exhaust clamp are all vital aspects when it comes to selecting and maintaining the appropriate exhaust clamp for your vehicle. By following these guidelines, you can ensure the optimal performance, efficiency, and safety of your exhaust system, contributing to a pleasant driving experience.